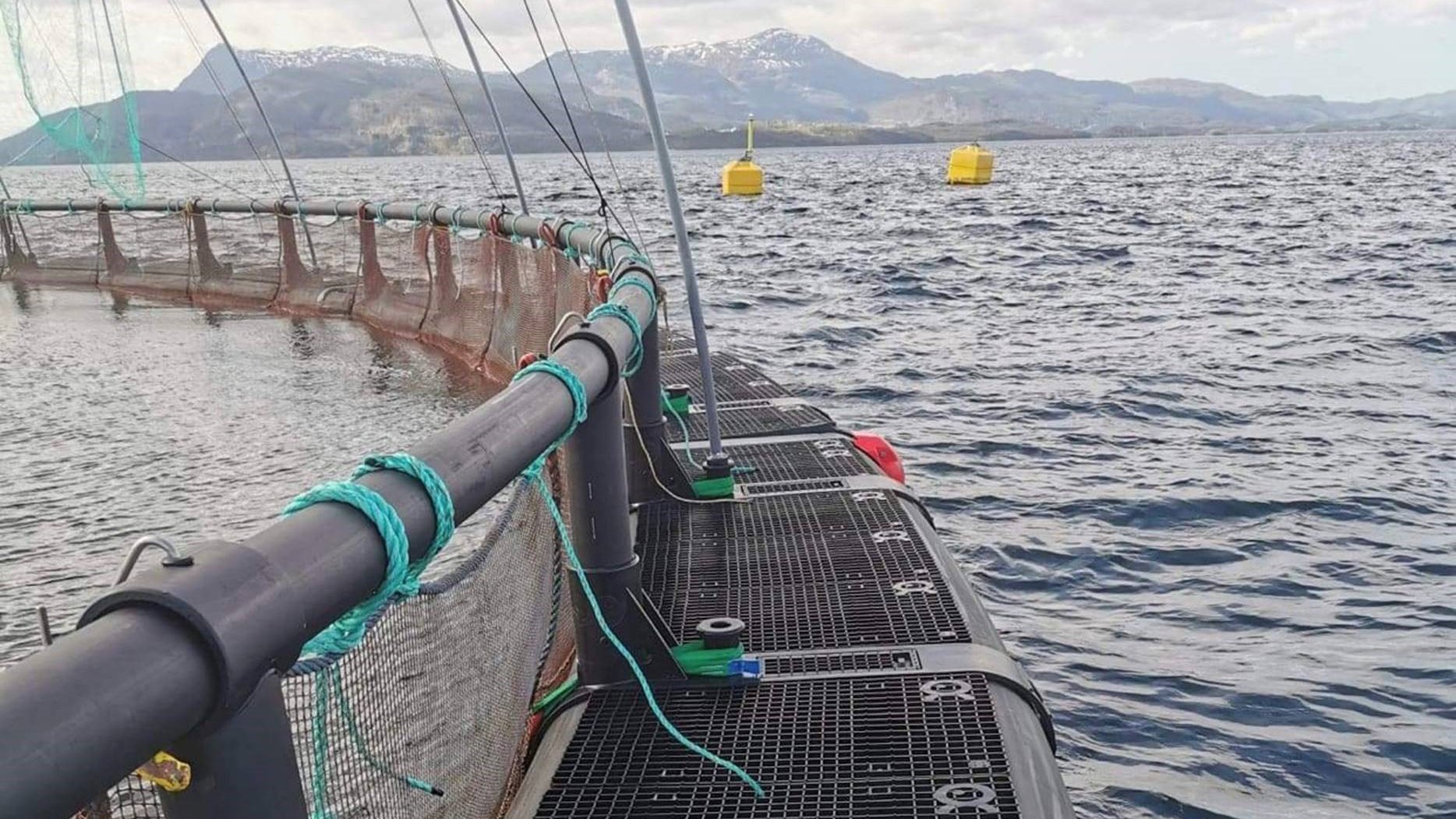

A pen free of polystyrene. Photo: AKVA group.

A pen free of polystyrene. Photo: AKVA group.

AKVA group wants to make pens more sustainable and has previously developed walkways in recycled plastic. Now, the entire pen portfolio is also free of polystyrene.

«Some time ago, we launched a new flagship pen – the 500R and 500RS series. In addition to its large capacity, this had an innovative solution with waterproof bulkheads as a replacement for the traditional solution with polystyrene in the floating pipes. Now we have taken an extra step and will produce all new pens without polystyrene. It is replaced by sectioning the floating pipes in waterproof chambers,” Arnstein Hosaas, R&D Director in AKVA group says.

The pens consist of almost 100 per cent HDPE material (high-density polyethene.)

“The quality is very good, and the product is more sustainable. The requirement for residual buoyancy in the event of pipe rupture is maintained, in the same way as the old solution with polystyrene. Waterproof chambers can in some cases increase safety in the event of an accident,” Hosaas says.

Less emissions

By cutting the use of polystyrene in pens, you also cut all emissions related to transport by car from the manufacturer to the installation site.

“From a sustainability perspective, it is important to reduce transport, and transport of polystyrene is particularly unfavourable because the product has a very low density. A fully loaded semi-trailer that can normally carry 30 tonnes, carries only about 2.5 tonnes when it is fully loaded with polystyrene,” Hosaas says.

All manual treatment of polystyrene from place to place is also problematic, according to Hosaas.

“It is inevitable that pieces of polystyrene are lost in the process when travelling all the way from the manufacturer, via transport to the installation site, intermediate storage at the factory or assembly site, installation of polystyrene in floating pipes and last but not least when disassembling old pens.”

Recycling

Hosaas says that the new pens are easy to recycle and reuse. In the disassembly process, you do not have to pay attention to polystyrene, which must be sorted separately. This makes it even less energy-intensive to make, for example, new walkways from discarded pens.

Hosaas is proud of the innovation, and makes an appeal to the industry:

“The entire aquaculture industry has a responsibility to make the right and important choices towards a greener future. The new polystyrene-free pens are a very concrete contribution in this respect from AKVA group,” he says.