Waterborne Feeding

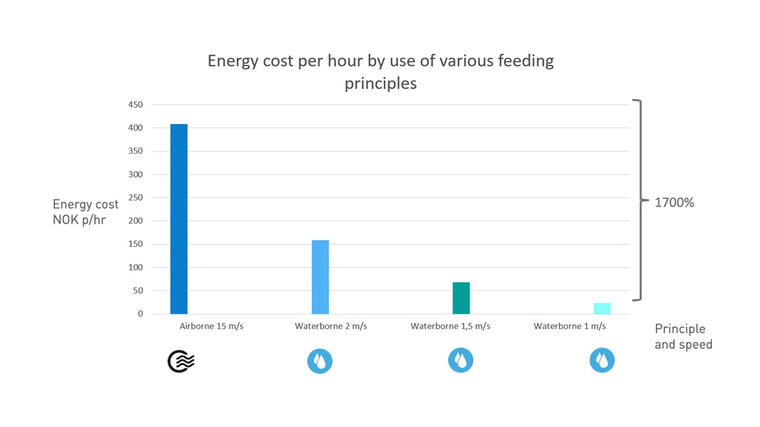

Up to triple the feeding capacity and gain huge savings in energy costs with Waterborne Feeding.

Up to triple the feeding capacity and gain huge savings in energy costs with Waterborne Feeding.

Waterborne Feeding is considerably gentler on both the pellets and the feeding pipe, and noise and micro-plastic discharge are reduced to an absolute minimum. You will also experience a significant drop in energy consumption by replacing air with water, and with pellet density no longer being an issue the capacity is more than triple.

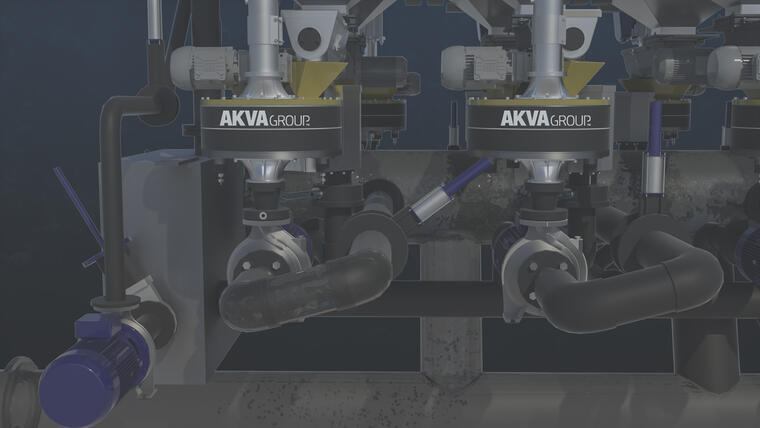

In this animation video, you see a waterborne feeding system in combination with the "Flexible feeding" concept, where feed is taken from the main silos to the buffer tanks associated with each line. The feed is then passed through the sluice where it is picked up by the water which carries it to the pen.

Green & profitable

Waterborne feeding will not only save you money, but significantly reduce the environmental impact of the farm.

Approx. 70 % reduced energy consumption represents a significant drop in CO2 emissions. With water being a much more gentle feed carrier, there will hardly be any wear of the pipes - meaning close to zero noise and micro-plastic discharge, and significantly prolonged lifetime for your feeding pipes. Water transportation does not impose the same requirements for antistatic feeding pipes, allowing you to switch to more affordable standard 90 mm pipes. It is also possible to submerge the feeding pipes.

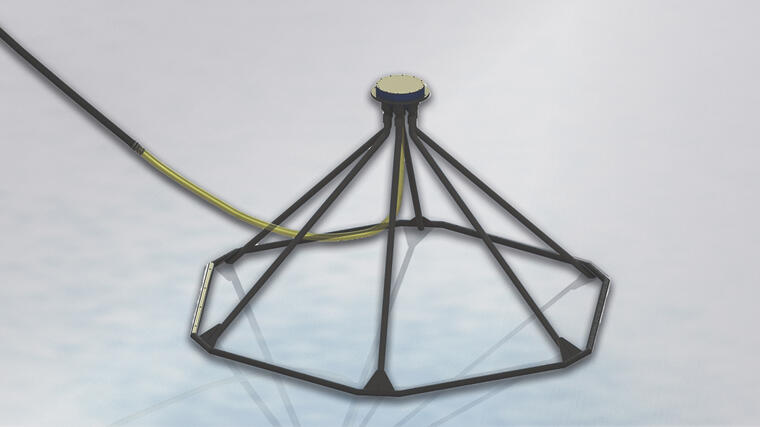

Our underwater spreader is designed for waterborne feeding. It can be placed at different depths and ensures good dispersion in the pen below the water surface. The feed is transported out to the pen by means of water transport down to the chamber at the top of the spreader. Then the feed is sent out via six distribution pipes with a spreading diameter of 5-6 meters. The feeding rate is up to 60 kg of feed per minute.

The feeding cameras show that the fish stay in deeper water around the feeding points most of the time. This results in good growth and good fish health as a result of reduced lice pressure.