Tubenet™ has managed the transition from research and development to commercial production extremely well and was launched as a commercial product in AKVA group in 2018. The first deliveries have now been in use for some time and we and our customers have gathered valuable experience. A new product introduced on the market must expect continuous product development, adjustments, and improvement in the initial phase.

We see that cooperation between customer and supplier is decisive for the success of Tubenet in sea lice prevention. This is especially important because the solution requires extensive changes to the production routines and AKVA group’s specialist personnel are an important resource in this adjustment process.

What results does Tubenet give?

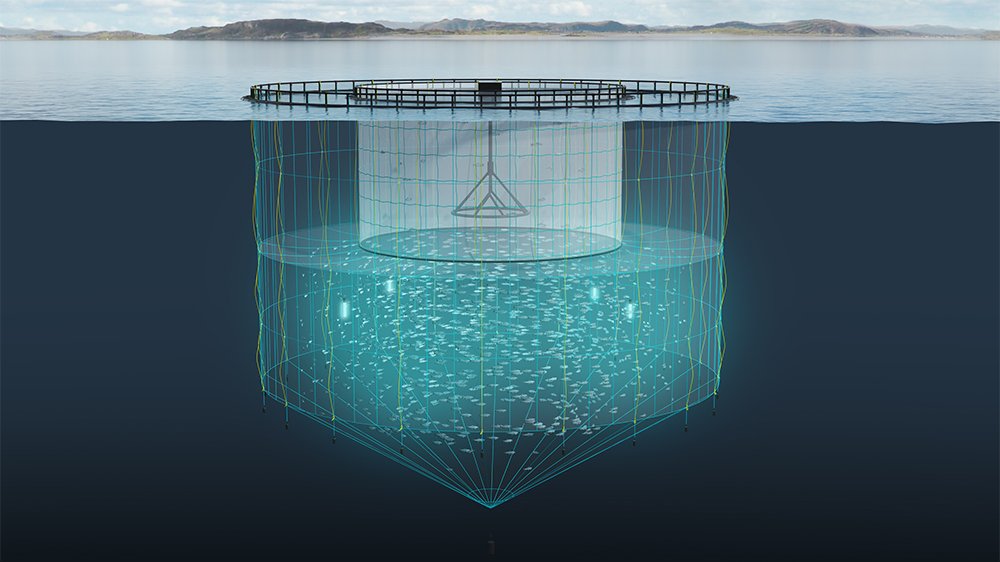

The principle of the salmon swimming in deeper water and Tubenet may not be completely clear to everyone, so a brief recap is in order.

In practice, Tubenet is an extra net inside the net. Combined with deep feeding and light control, Tubenet helps keep the fish in deeper water where the lice presence is minimal. Lice presence decreases with the depth of the tube.

In this article (in Norwegian), you can read about the Institute of Marine Research’s latest research on the effect of light on salmon lice.

Let us take a closer look at our experiences with Tubenet in commercial production.

• Our customers experience a significant reduction in lice infestation

• The number of lice treatments per generation is reduced

• The number of feeding days increases

• Reduced mortality by avoiding lice treatment

• Improved fish welfare

• The total costs of lice treatment are reduced

• One or two lice treatments can be enough to defend the investments in equipment and the changed production process

Our customers help improve Tubenet

There can be a significant difference between a product in the research and development phase and a product in commercial production. Tubenet has been reinforced and improved but adjustments are still required. This research and development work is carried out in close cooperation with the production teams at the fish farms.

An example of such an improvement is how we solve the challenge of the hourglass effect that can be experienced in the tube. Due to differences in the temperature and/or salinity of the water, we found that the tarpaulin contracted towards the centre. This problem was solved by fitting a valve that allows surface water to enter, balances the tarpaulin and keeps the access to the surface wide and cylindrical.

Enthusiastic fish farmers

We can now safely say that Tubenet is a tool that works as we had hoped and as we all know, a good tool is a key success factor. However, it is equally important that each production manager and the team at the farm are prepared to focus on prevention. They must believe that it is possible to reduce the number of lice treatments to a minimum.

The final factors that must be in place are help, support and training in establishing a new production process. Here, the professional staff in AKVA group will provide important expertise and experience. We are as willing as our customers to have a successful project and see that cooperation between customer and supplier is decisive for achieving this goal. We now know that the tool works as a preventive measure against salmon lice.

Please see the movie from Mowi's Tubenet installation