Service & support - Land Based

Let AKVA group take care of the technology while you focus on keeping your fish in good shape. We offer global service and support on all our products and solutions to match any need.

Let AKVA group take care of the technology while you focus on keeping your fish in good shape. We offer global service and support on all our products and solutions to match any need.

Opening hours:

08:00-16:00 (CET / CEST)

Service and support are becoming an integrated part of our business to enhance the performance of Land Based fish farming.

Advanced aquaculture needs professional maintenance, training and documentation.

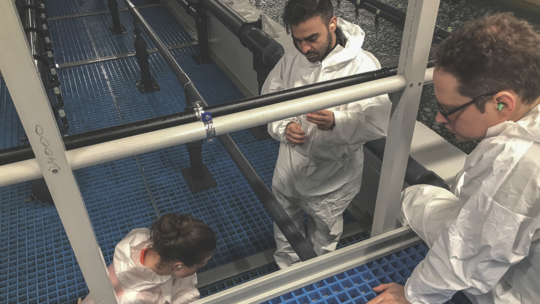

As aquaculture equipment and solutions becomes more advanced, the need for professional service and preventive maintenance increases. AKVA group offers global service on all products and solutions. Our technicians will arrive on-site to get a complete overview and understanding of your specific needs, whether these are technical issues or biological challenges.

![]()

Hardware

T: + 47 51 77 85 03

E: supportakvasmart@akvagroup.com

Opening hours:

08:00-16:00 (CET / CEST) + Extended Hours:

Mon-Fri: 06:00-08:00

Mon-Fri: 16:00-24:00

Sat-Sun: 06:00-24:00

Let AKVA group take care of your system with a service agreement.

Your success is our success and therefore we strive to provide operational reliability for our customers.

We offer service agreements for RAS systems and feeding systems. Contact us and let us setup a meeting to discuss what level of service you need.

If you are in need of spareparts, equipment or manuals please contact us.

You can also call us for urgent requests for spareparts please.

For operational reliability, please order in good time as we sometimes experience long lead times.

Parts with long lead times are mostly:

Yes, a RAS requires a lot of electricity. The consumption depends on species in production, temperature of rearing water, local climate conditions, system heating or cooling, system design, size of system etc. The energy consumption will vary throughout the year or the production cycle as the fish gets bigger. There is also a difference in consumption if it is a Grow-out RAS or a Smolt RAS, the latter being more energy efficient per kg fish produced, mainly because of better feed utilisation in smaller fish resulting in a lower requirement of water treatment.

The RAS system itself uses most of the electricity, such as pumping of water and degassing using air blowers. The cooling of the process water can also be costly as the fish creates heat when they grow. Some farms save energy by passing cold seawater through the heat exchanger to cool down the RAS process water, whereas most farms use electrical chillers for heat exchange.

AKVA group is continuously looking into more energy efficient solutions, making sure that customers are always offered our most energy effective systems.

The development land based fish farming projects has grown rapidly in recent years. AKVA group has delivered more than 100 systems, mainly within the technology of RAS (recirculation aquaculture system). Our technology and solutions have been used in fish farming for decades and the projects have grown in size and complexity which calls for an even more structured and professional approach.

In order to ease the early development phase, we focus on making a proper preparatory work to meet customers needs and line up the road map for the project execution. The fish production plan is of utmost importance and needs to be both cost-effective and must result in healthy and high quality fish. We have many years of experience in finding the most optimal solutions based on our well proven farming modules.

There will always be some degree of risk involved in the different project phases. In the early phases while engineering and designing the facilities AKVA group uses risk analysis to minimize these risks and to prevent mishaps during construction. Once the farm is completed and tested, we will train the operating personnel in the start-up phase and provide follow-ups during the full production. The importance of having skillful personnel and precise operating routines cannot be underestimated.

Our PAS team (Production Advisory Service team) will support the farm personnel in improving system operations, such as biofilter maintenance, water quality testing and more to take full advantage of the designed production capacity. With the support of our PAS team, customers will receive direct expert knowledge in fish biology and water chemistry, hereto our service engineers will be available to ensure that the technical installations are working correctly.

The establishment of a land based fish farm is a huge task that calls for proper preparation before the execution of the project can take place. This pre-phase is to ensure that customer needs are well defined and the appropriate technology is designed to meet the specific needs. Changes in design in later phases always leads to cost increases and postpone start-up of the facility.

Examples of customer needs are fish production plan, flexibility in fish handling, intake water treatment, sludge handling etc. Other items of more general importance are the limitations of footprint, the scope of work by AKVA group (SOW) and the division of responsibilities between customer, local contractor and AKVA group (DOR).

AKVA group uses risk analysis to mitigate the risks while designing and constructing the facilities. Our teams of dedicated engineers, designers and biologist work systematically to ensure that design fulfills the needs, and that the operation of the facility becomes as efficient and smooth as possible.

Further to reduce risks, we will train the operating personnel in the start-up phase and provide follow-ups during the full production. The importance of having skillful personnel and precise operating routines cannot be underestimated.

Risk mitigation is also obtained by the support of our PAS (Product Advisory Service) team, our expert in fish biology and water quality management who advises customers on-site and on-line. The same counts for our service engineers who are making sure that everything is maintained and working correctly according to a service agreement.

All food production has an impact on nature, whether we speak about the area that a production occupy or the discharge from a facility. The level of impact depends on the location, the farming area, the volume of production, the system design and the discharged amount and the content.

All the plants are built in industry-regulated areas. This means that the areas have been selected and approved by the authorities for this specific food production industry. Many of the fish farms are placed in already established industrial areas. It is the local government that decides what can be built and the impact on nature is always considered before any approvals are given. Prior to the execution of a project, the permit is either approved for a limited period or on a permanent basis.

To minimize the impact on nature, we have introduced the zero water concept (ZWC) in our recirculation aquaculture systems (RAS). This technology brings down the nitrate and phosphorous levels and reduces the water consumption by 99%. The technology also makes it considerably easier to retain all sludge and treat the effluent water to meet the consent levels permitted. The accumulated sludge can be used for soil improvement and fertilizing or for biogas and biodiesel.

Our teams of engineers and biologists are always ready to support customers in identifying the most efficient treatment technologies to meet the requirements for a sustainable production.

All food production has a sustainability impact and so does land based fish farming. However, the development of the recirculation aquaculture system (RAS) has made land based fish farming much more sustainable. Compared to traditional land based fish farming RAS technology is environmentally friendly, and the systems can be set-up almost anywhere in the world.

The main sustainability benefits of RAS are:

The impact on nature is reduced by the zero water concept (ZWC) connected to our recirculation aquaculture systems (RAS). This technology brings down the nitrate and phosphorous levels and reduces the water consumption by 99%. The technology also makes it considerably easier to retain all sludge and treat the effluent water to meet the consent levels permitted. The accumulated sludge can be used for soil improvement and fertilizing or for biogas and biodiesel.

The biggest sustainability challenge with the RAS technology is the electricity use. AKVA group design farms to minimize the consumption of electricity, and customers normally buy green electricity from wind or water turbines in addition to adding sun panels on the roof of the fish farm.

COMBINING LAND BASED WHIT SEA BASED

Post smolt is smolt produced bigger than a traditionally sized smolt. When the salmon fry reach the smolt stage they are ready for release into the sea based net pens for on-growing. The traditional size of smolts is around 100-200 grams, but bigger sizes have many advantages.

Larger smolt increases harvested volumes due to shorter time in sea which allows for better license utilization, as new smolt can be introduced more frequently. The lager smolt implies larger production at land which can be added to the production at sea. Producing more on land allows for more efficient production cycle. This can either be used to increase production in sea or keep sea production constant. Typically, the use of bigger post smolt, will reduce the overall production time from fry to fully-grown salmon by 3-4 months, depending of course on the harvesting size.

Larger smolt improves the fish health; the fish is more robust, and reduced time at sea leads to lower disease pressure and sea lice exposure. Improved fish health means that it gets an improved survival rate from less exposure to biological risk, reducing cost of mortality and biological treatments. The post smolt strategies most often result in lower mortalities overall, it also improves the feed conversion rate (eFCR), this because of a bigger end-biomass ready for harvest.

Typically, a Post-Smolt will be at sea for around one year, whereas a traditional Smolt would be at sea for one and a half year, before it is ready for harvest. The shorter period at sea gives the nature more time to recover if the following periods are extended, or potentially reduces fish escapes from fewer accidents when intervening whit, the fish. This better the environmental footprint.

Land based fish farming will create new local jobs for personnel operating the facility. Hereto comes administrative staff and employees in sales and marketing.

Also, employment among established companies in the area might be positively affected. Local companies are often used for practical reasons for installation work, service and maintenance. In the construction phase there will be an increased need for personnel which may indirectly lead to more jobs in the immediate area. As the plant is completed, the need for labor will gradually decrease. Finally, the operating personnel will hold the permanent jobs at the plant. The number of positions depend on the size of the facility.

In addition to direct jobs related to the facility, the increased activity in the area may lead to ripple effects on other local industries such as shops and service companies. Examples of these are electricians, plumbers, cleaning staff etc.

AKVA group's feeding systems ensure optimal utilization of the feed. The system is based on a technology that preserves the quality of the feed keeping the pellets intact when being fed into the fish tanks. The feed pellets are eaten readily by the fish securing that pellets are not falling to the bottom of the tank. It is essential that all feed is eaten to avoid spillage and to gain as much growth in the fish biomass as possible. Efficient feeding and maximized feed uptake in a recirculation aquaculture system (RAS) will increase the performance:

AKVA group´s Research & Development team conducts extensive research in fish feeding behavior for the development of the best suited technologies and software solutions. Having the basic in order is essential: Clean water of high quality and the right temperature that has been biological treated and aerated secures an efficient oxygen intake over the gills allowing the fish to utilize the feed extremely effectively when digested. This results in rapid growth of healthy fish.

Yes, the off-flavor components can affect the taste of the fish meat. Off-flavor is not a problem in all the RAS production, but it can be an issue in RAS when the system is highly loaded. Because of the high level of re-cycling and the small rate of new water coming into the system, there is a risk of off-taste coming from flavor-producing bacteria living in the biofilter and the biofilm in the system. One component is geosmin that you smell in rain in the summer or detect when eating vegetables but having the component in the fish is most often disliked by consumers.

The off-taste problem does not affect smolt and post-smolt production as these fish are transferred for grow-out at sea sites. The off-flavor component will disappear quickly once the fish are growing at sea. In the land based grow-out systems however, the off- flavor components can be an issue. The removal of geosmin in fish on land is carried out by having the fish in clean geosmin-free water for 7-10 days. This prosses is called purging or depuration and removes the off-flavor components from the fish tissue and fat.

AKVA group´s Research & Development team is working together with world-leading experts to prevent the formation of off-taste in land based aquaculture. The results are promising, and we are developing new methods of managing off-taste.

AKVA group will help you out from project idea and all the way to the stage of operating your Land Based fish farm.

In AKVA group – our customers success is our success. Therefore, we are proud to have our very own “Production Advisory Service” (PAS) team. The team’s main objective is to maximize the performance, health and quality of fish produced in our customers land-based fish farming facilities.