To overcome the salmon louse, the industry has used garlic, lasers and chemicals, closed pens have been built and technology has been developed that separates salmon and lice. Some measures have a demonstrable effect, while others have had no effect at all. But the aquaculture industry has learned quite a lot over the last 40-50 years. Believing in an invention that is a universal miracle which, as if by magic, removes all problems related to salmon lice, while retaining both quality and economy, does not seem very realistic.

As the largest supplier of equipment to the Norwegian aquaculture industry, and a major international player, AKVA group are at least as dedicated to combating sea lice as the fish farmers themselves.

Salmon lice has an incredible talent to multiply with some very short generation times, which makes delousing incredibly difficult. Any method that is initially effective will lose its effect in a short period of time because the sea lice that survive the treatment are naturally those that multiply further, and also with genetics that are most resistant to the treatment in question.

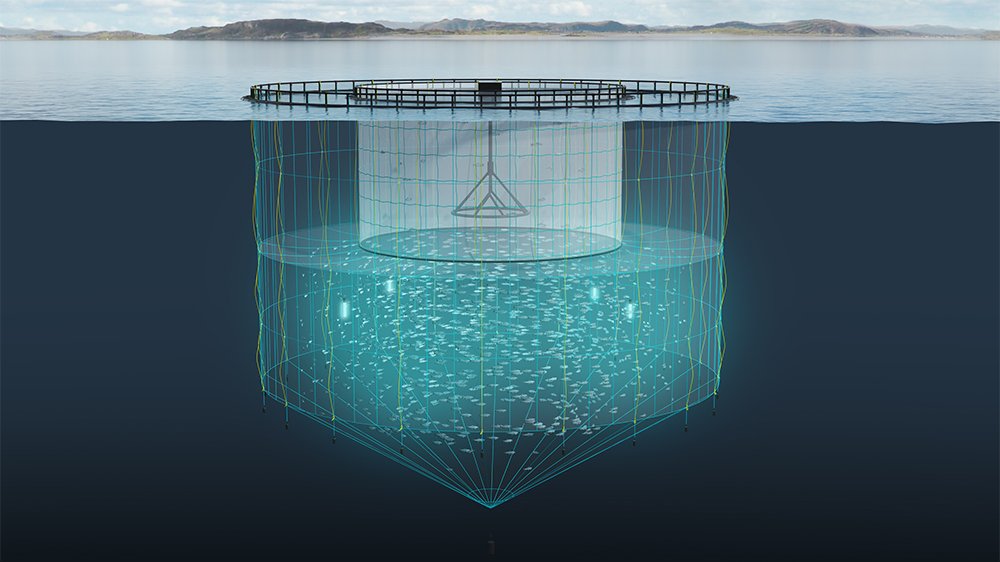

Positive experience with deep operation

We must live with treating salmon for lice in future, but, at AKVA group we have focused our efforts on avoiding any lice infestations whatsoever.

Our primary strategy for avoiding lice infestations is simply to keep the salmon away from water layers where the salmon lice larvae are located. In a number of experiments, the Norwegian Institute of Marine Research has shown that sea lice primarily remain in the top 10-15 metres, thus allowing us to avoid exposing the salmon to the water masses where the lice larvae are located.

Our ten years’ experience with Tubenet™ has given us quite a lot of useful experience. We have well documented results indicating the solution is highly effective as a preventive measure against sea lice. Furthermore, we find that good results are contingent upon variables other than simply using a new tool. We note that adopting a system, which protects against lice is much more demanding for a fish farmer than simply purchasing components they are comfortable operating.

Tubenet introduces new operating routines and a different way of operating. These are purely technical challenges and we have painstakingly become aware that not all solutions work well in all locations. Understanding local currents and wave conditions is crucial to achieving good results. We now have experience from 70 sold Tubenet units. In recent years we have experienced very positive developments with respect to the effectiveness of Tubenet. We believe the fact that the product has been improved from a technical perspective and that fish farmers have gained more operational experience, and are increasingly playing together as a team, is the main reason we now see the best results ever from using Tubenet.

Read more:

Watch a short introduction on Tubenet™ here:

Salmon without lice is possible

Well, we will not maintain that the industry is free of lice issues, but we have taken some important steps towards being able to offer and provide guidance in the use of Tubenet, which protects against lice infestations without involving either chemical or mechanical treatment of salmon.

These results motivate us to proceed in our quest to solve our "tiny little problem." We continue to gain more knowledge about how local conditions impact the solutions, we collaborate even more closely with the fish farmers to be able to assist them in a more active way, and naturally we continuously improve our products so that they are even better. We are also committed to working closely with Frode Oppedal's group at the Norwegian Institute of Marine Research, which has expertise in fish welfare and behaviour in deep operations, and the group is at the forefront of its research on this topic.

A generation of salmon in the open sea, kept at a depth of 100grams to 5kg is possible without a single delousing, we know that, now we will just help the fish farmers to do it more often!

{{cta('3d215692-fa38-4b20-b0f0-c6c9495436f1')}}

See installation of Tubenet™ for MOWI at their location in Bastli, Norway: