Pipes

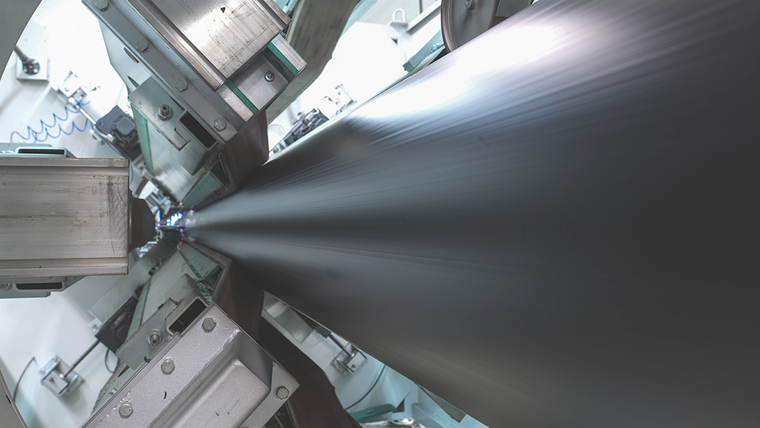

We use only the best quality raw materials and document the pipe production process via an in-line scanning system. The results are well worth the effort, our products are robust, maintenance-free and have a long service life.

We use only the best quality raw materials and document the pipe production process via an in-line scanning system. The results are well worth the effort, our products are robust, maintenance-free and have a long service life.

Polyethylene (PE) has a number of beneficial properties that make it eminently suitable as a pipe material, including high flexibility, no corrosion or wear due to electrolytic processes and no risk of attack by living organisms.

The unique rust-free properties, the chemical advantages and extra long life are the reasons why mining companies and the process industry have polyethylene as a clear first choice when it comes to pipe material.

We offer a wide range of PE pipes for water supply and drainage, all of top quality and properties such as leak safety, flexibility, "organism-free" surface and extra-long service life.

We can supply pipes up to 1200 mm in outer diameter and up to a maximum pressure of 20 bar on pipes up to 800 mm. We can also calculate and adapt the pipe dimensions and pressure in relation to the flow. The extremely smooth surface of PE pipes ensures superior flow.

Corrosion-free and flexible PE pipes are perfectly suited for telecom installations.

We supply flexible and practical feed pipes to the aquaculture industry that are designed to withstand extra harsh weather conditions. In addition, we produce pipes and parts for Polar Circle cages and service boats.

We supply pipes and fittings to smolt facilities and land-based fish farms.

We have one of Europe's most modern production lines for PE pipes and can supply certified special pipe dimensions that are non-standard.

Our certified pipe installers ensure accurate and safe installation. Mirror welding is the most common method of assembling pipes.

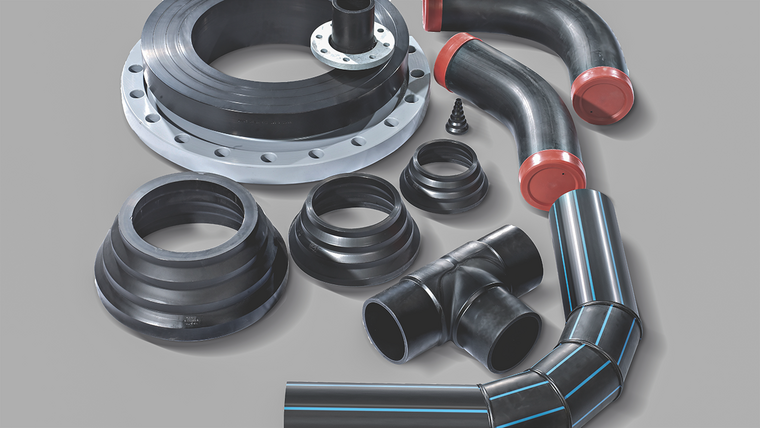

PE pipes and fittings are used for a variety of purposes, such as water supply, sewage systems and for the transport of chemicals, toxic liquids, sludge, food and agricultural products. (Photo: Mads R. Steen).

We offer complete piping systems for both high and low compressive loads. Welded or injection moulded PE fittings include: Elbows, bends, T-pieces, plugs, transitions, strainers, manifolds, collars, flanged connections, electromechanical couplings and much more.

We use only the best quality raw materials and document the pipe production process via an in-line scanning system. The results are well worth the effort, as our products are maintenance-free and have a long service life.

We have a large capacity with four extruder lines in modern production facilities. We can manufacture PE pipes with diameters from 20-1,200 mm and in lengths of up to 500 meters.