Atlantis Subsea Farming

Submersible fish farming facilities for salmon

Submersible fish farming facilities for salmon

Further development of proven technology

AKVA group has been working on submersible cages for a long time and the first project was already delivered in 1991. So far, AKVA group has sold 500 different varieties of submersible cages, but the system that is now being developed for salmon is far more automated and advanced.

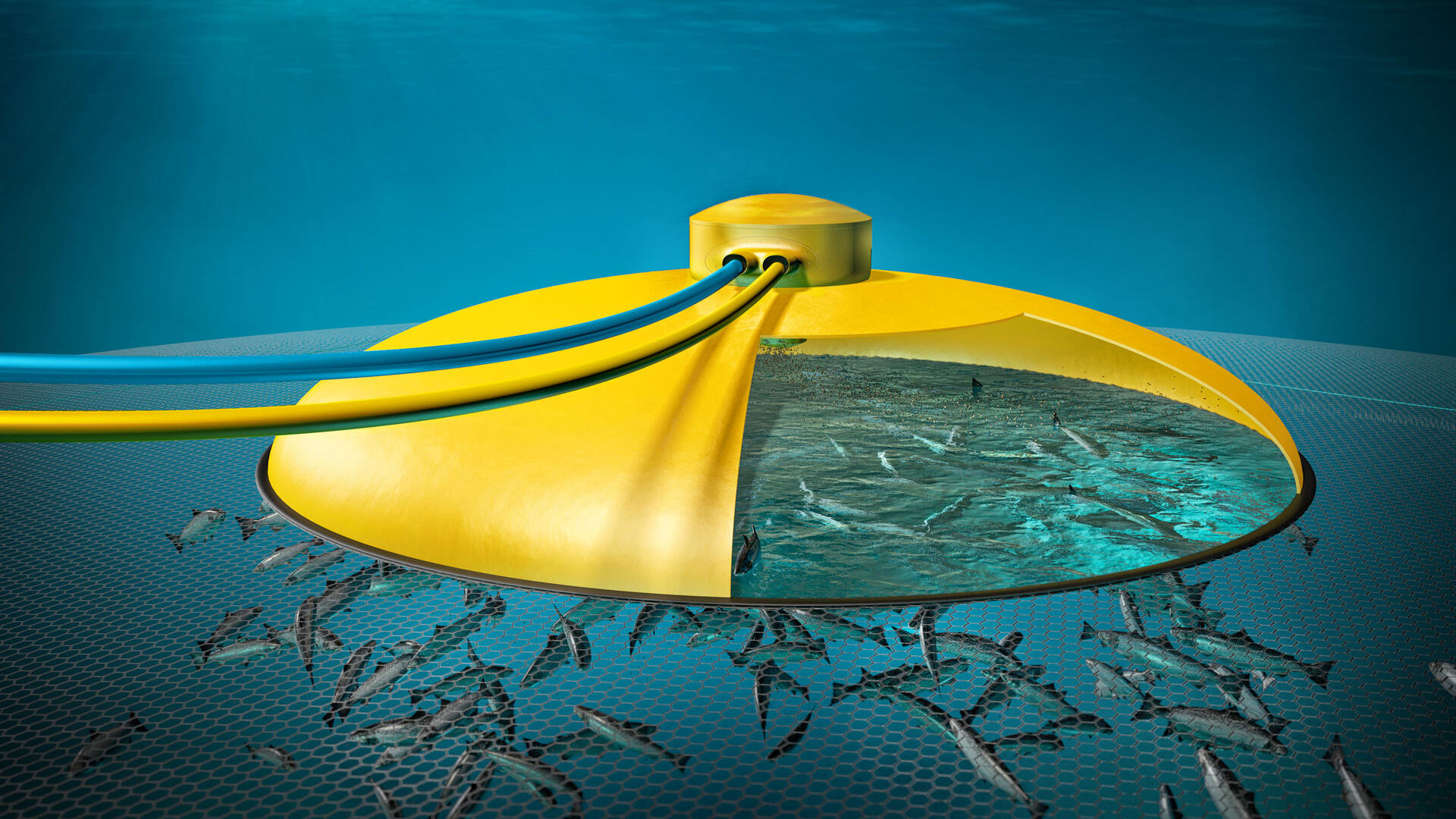

Moving the salmon through the water column presents many challenges that must be solved. One of the largest challenges is the creation of the artificial airspace the salmon needs to fill the swim bladder and maintain normal behavior. The salmon is dependent on filling the swim bladder regularly and it must be done without having to raise the cage to the surface. Creating an artificial air pocket that the fish will use is challenging, and technology and biology must cooperate in order to get the desired result.

Knowledge-based technology

In collaboration with Frode Oppedal and his research group at the Institute of Marine Research, AKVA group has for several years been working systematically in order to obtain knowledge about fish behavior related to the use of air dome and feeding in submerged cages. The FÔRDOM project is funded by the Norwegian Research Council, AKVA group, Egersund Net and Sinkaberg Hansen. The results from this research are directly relevant to the work in Atlantis.

Atlantis has also carried out several tests in SINTEF Ocean's Flumetank in Hirtshals, which has provided very valuable knowledge about how the overall construction behaves under different environmental conditions.

The technological solutions

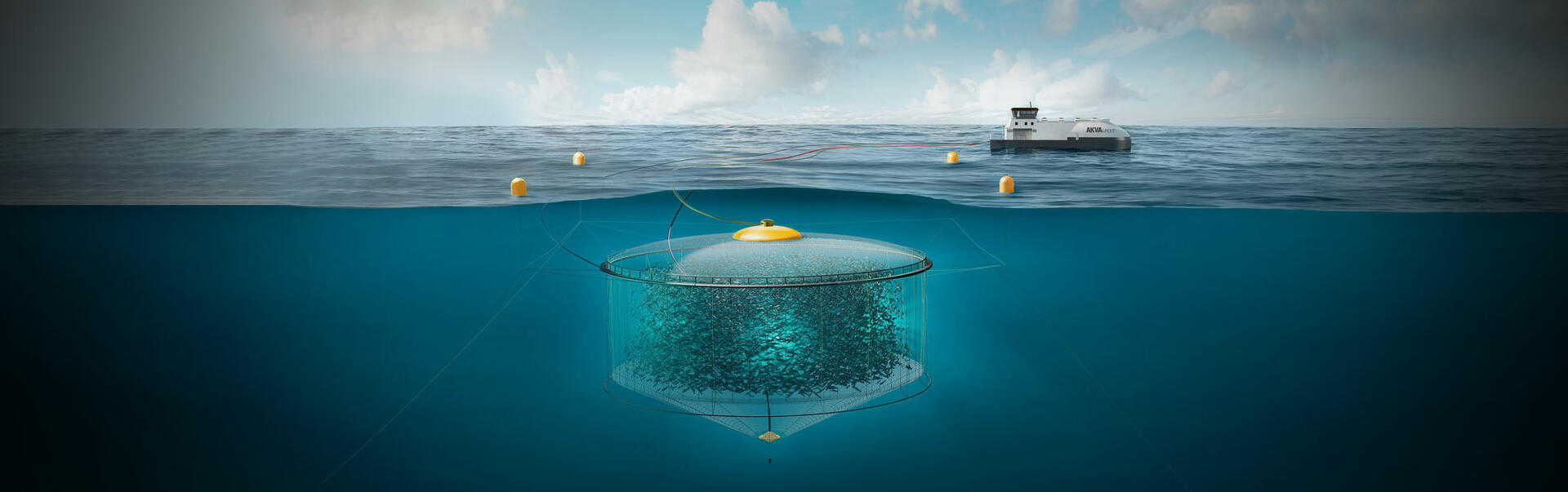

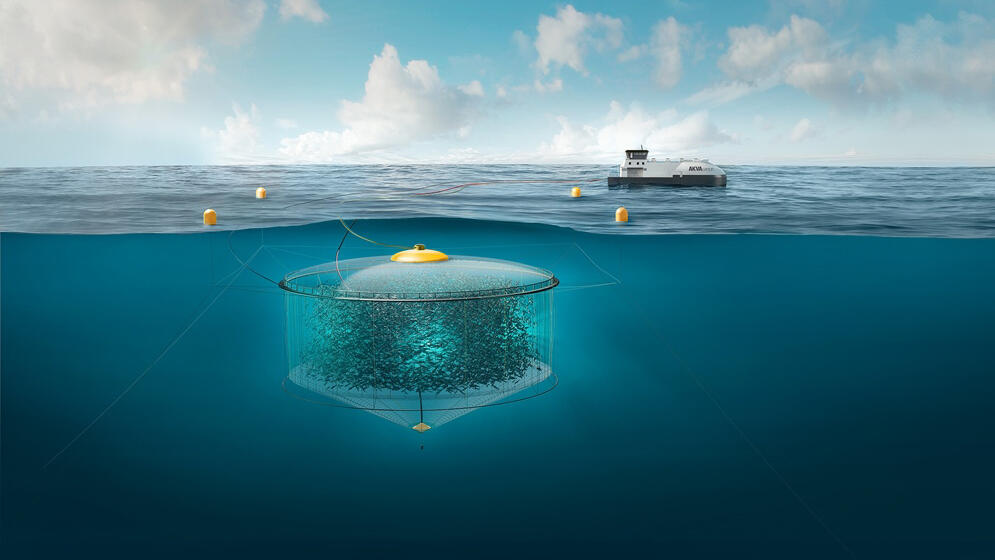

The Atlantis Cage to be tested is 160 meters in circumference and is made of PE pipes filled with water for immersion and air for elevation. The cage is lowered to 15-20 meters and the goal is to keep the cage submerged 80-90 percent of the operating time. The lifting and lowering function is controlled by the control system AKVAconnect and the cage can be controlled from the feed barge or land. The frame extension is built with specially designed buoys to withstand significantly more buoyancy than conventional buoys. The system is thoroughly tested and verified due to the significant forces at work. Even though the technology is well-known, the concept requires considerable innovation in several sub-projects.

As the buoys are the only visible objects, monitoring of both fish and plants is crucial. This means equipping the entire plant with instruments such as different types of sensors and cameras for monitoring and control.

Security and collaborations

In Atlantis, several new technical solutions have been developed and will be tested on a large scale over three generations. An important part of the project is to monitor fish welfare and the growth of the plant. Another important element of the project is to have a third-party assessment of the design process and the construction phase, as well as to execute the certification process according to requirements in NS 9415.

The Atlantis project would not been possible without close cooperation between the owner companies and external suppliers and partners. The interaction is crucial for a good result. The actual testing of the pilot cage will take place at sites near Rørvik in Nord-Trøndelag, Norway, where the project has access to expertise and necessary equipment from a complete industry cluster.

In 2014, AKVA group ASA, SinkabergHansen AS and Egersund Net AS started to work on developing submersible fish farms for salmon. The three companies established Atlantis Subsea Farming AS (Atlantis) to move the production deeper into the water column. Atlantis would not been possible without close cooperation between the owner companies and external suppliers and partners. The interaction is crucial for a good result.

Aquastructures, KB Dykk, Partnerplast, Val Fou, Havforskningsinstituttet, Nærøysund Aquaservice, SINTEF Ocean & Xylem Water Solutions.