Netting

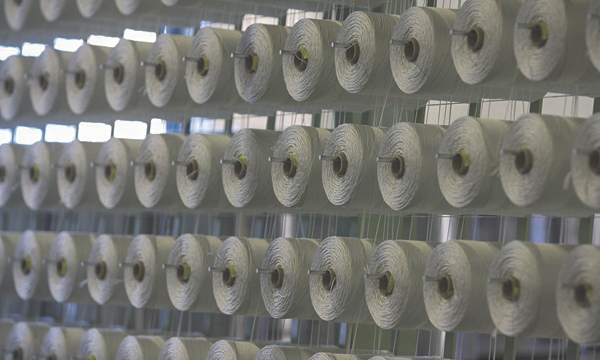

We have a high focus on continuity and efficiency throughout the whole manufacturing process, from the manufacturers of the filaments to the end product.

We have a high focus on continuity and efficiency throughout the whole manufacturing process, from the manufacturers of the filaments to the end product.

Netting made in Norway. A high level of flexibility, capacity and the ability to quickly adapt to changes ensure fast delivery. We have a high focus on continuity and efficiency throughout the whole manufacturing process, from the manufacturers of the filaments to the end product.

We have full traceability in our production process.

Egersund Net uses filaments from reputable suppliers.

Long-term cooperation with suppliers ensures the best technical solutions.

We deliver superknot, hexagonal netting, standard knotless netting as well as a variety of knotted netting. Our netting is manufactured of Nylon P6, Entex or Dyneema® filaments.

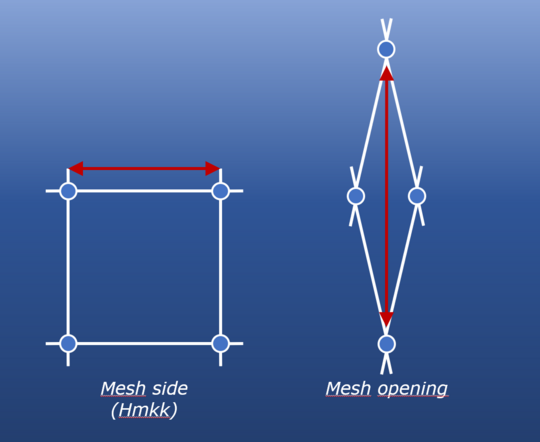

Our netting is manufactured with a meshwidth of 1008 meshes, and we are able to produce netting with a breaking strength from 36 kg up to 210 kg.

Our highly qualified employees have been with us for many years, gathering a great deal of experience, competence and understanding of product characteristics.

"High quality netting"

DOWNLOAD NETTING TABLE NYLON (PDF, 111KB)

AKVA group invests major resources in product development and testing of models in cooperation with our customers.

A test tank belonging to SINTEF Fisheries and Aquaculture is often used in order to improve our knowledge about various designs. The test tank allows simulation of various currents and wave conditions.

Net in 0.5 knot current.

Net in 1.0 knot current.

Net in 1.5 knot current.

Testing of materials

Our laboratory is equipped with advanced technological equipment for verifying the characteristics of ropes and other materials. All components are carefully tested and documented before being implemented in any of our products.

New models are carefully documented under various conditions in a flume tank by SINTEF in Denmark.

Detailed small-scale models of net designs are used for testing.

The test tank is also used in cooperation with customers in order to solve challenges related to local operation and the preparation of new working procedures.

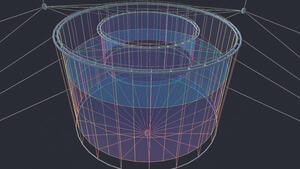

A 3D illustration of a new tubenet concept.