Treatment of nets

We have developed an indoor treatment facility for nets.

We have developed an indoor treatment facility for nets.

Treatment of nets - coating and antifouling

A high level of safety during the production process, and optimal results from treatment. Egersund Net has developed an indoor treatment facility for nets.

Our net treatment facilities ensure identical conditions throughout the year and has a high level of efficiency.

We put a great deal of emphasis on the safety of operations during the production process. When the net has been suspended and is ready for treatment, dipping, drying and packing is executed in a single operation. This reduces the risk of damage being caused to the net.

However, the most important thing is that the result from the treatment of a net will be optimal. We do this by impregnating the nets by a process based on dipping, to ensure that the absorbsion of coating or antifouling is optimal.

We are currently offering coating and antifouling products from NetKem, Steen-Hansen and Brynsløkken.

Our employees exchange information on a continuous basis, and are working in accordance with "best practice" philosophy. Egersund Net is recognized for its skillful and professional employees. This is one of the reasons our customers can rely on us.

"Optimal treatment of nets"

We focus on quality during the entire process, dipping, drying as well as net handling.

AKVA group invests major resources in product development and testing of models in cooperation with our customers.

A test tank belonging to SINTEF Fisheries and Aquaculture is often used in order to improve our knowledge about various designs. The test tank allows simulation of various currents and wave conditions.

Net in 0.5 knot current.

Net in 1.0 knot current.

Net in 1.5 knot current.

Testing of materials

Our laboratory is equipped with advanced technological equipment for verifying the characteristics of ropes and other materials. All components are carefully tested and documented before being implemented in any of our products.

New models are carefully documented under various conditions in a flume tank by SINTEF in Denmark.

Detailed small-scale models of net designs are used for testing.

The test tank is also used in cooperation with customers in order to solve challenges related to local operation and the preparation of new working procedures.

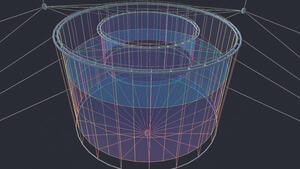

A 3D illustration of a new tubenet concept.